Test purpose

Evaluate the error detection capability of the IQM system.

Test method

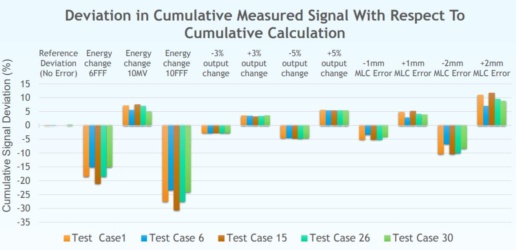

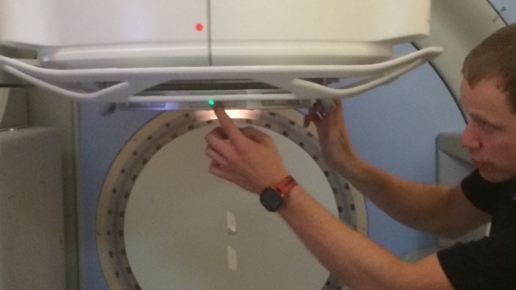

32 Head & Neck VMAT test fields (with 110 segments each) were calculated using the IQM CALC application, then delivered by a TrueBeam LINAC for 15 fractions over a course of 50 days.

The error detection capability of the IQM system was tested by introducing the following systematic errors into 5 randomly chosen test plans: ±3% and ±5 % change in total MU (simulating machine output change); ±1 mm and ±2 mm change in MLC bank position (simulating calibration error); and energy mix-up from 6MV to 6FFF, 10MV, and 10FFF. The differences in measured and calculated cumulative signals were then quantified.

Conclusion

IQM is capable of detecting 1mm error in MLC bank position, change in machine output by >3%, and any mix-up of beam energy.

This test report is based on a publication created by Princess Margaret Cancer Centre, Toronto (Canada).

Please click on the „Download“ button to download the complete publication.